I can't remember if I shared this, but one of the first things that happened to the first Seagull ST3600 I bought, is that the balance wheel simply fell off during reassembly! I assumed I must have been too rough with it, but as it turned out, there was insufficient adhesive on the stud to keep the hairspring in place.

So into a box it went, as I continued to work on its replacement. In the back of my mind, I wanted to come back to it once my skills (and magnification) were up to the task. So I took a stab at it today, with some UV glue, and a working balance for reference.

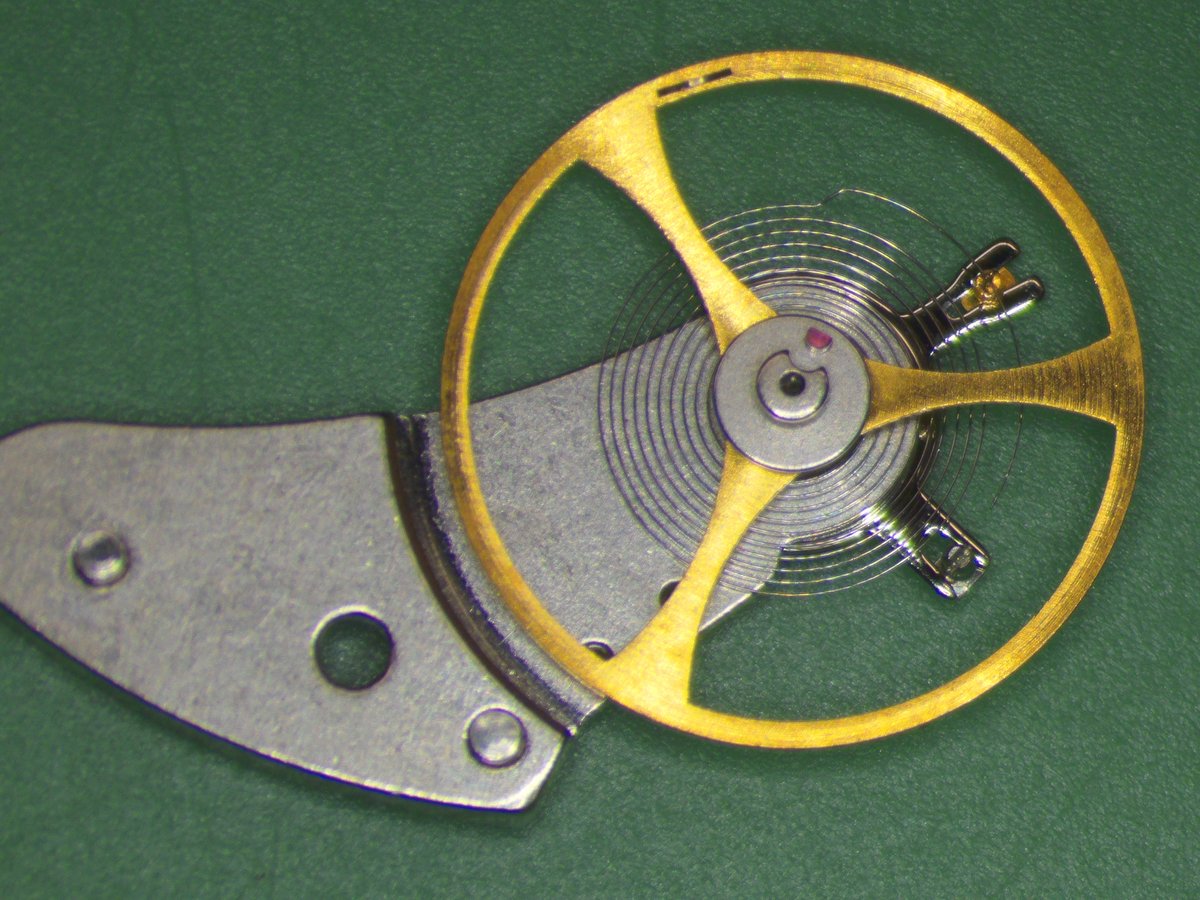

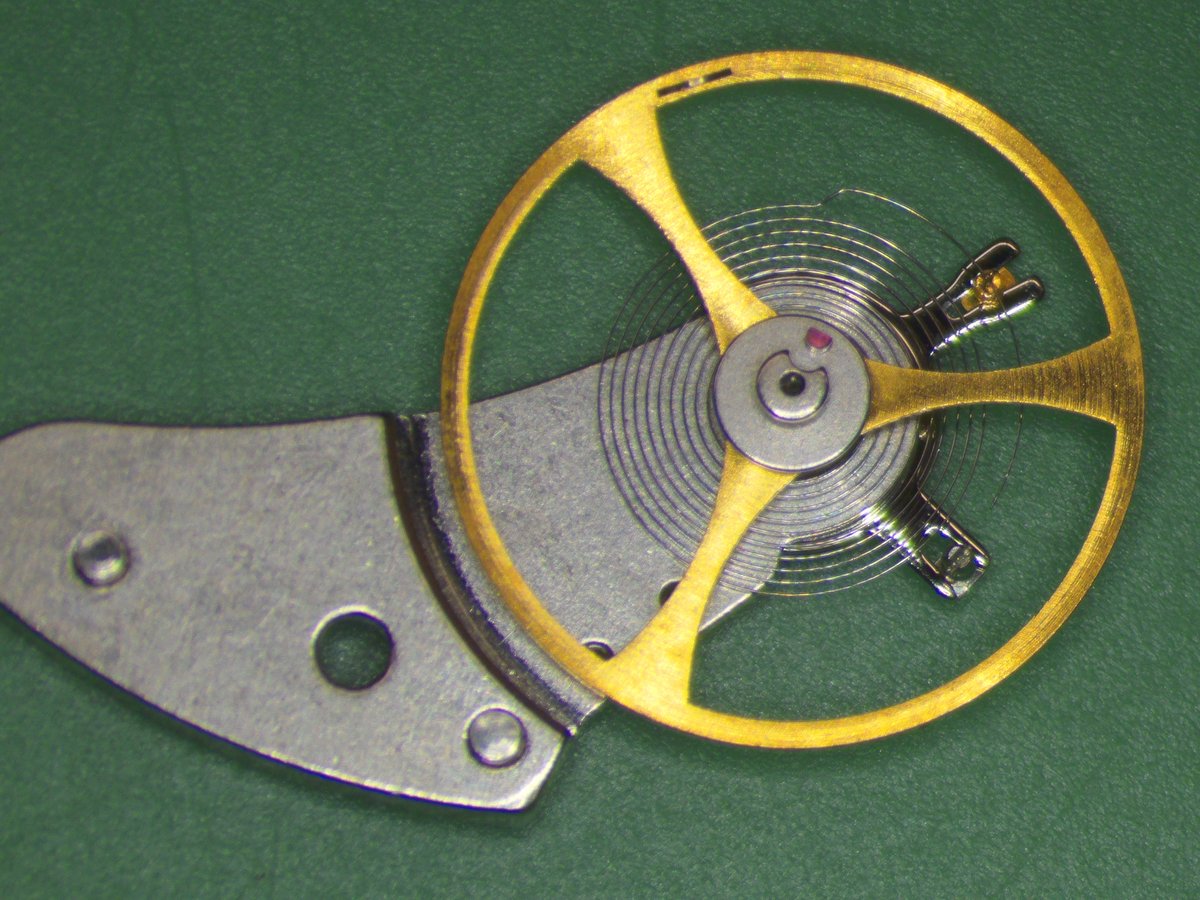

Here's the balance cock with balance removed (well it fell out). No trace of glue on the stud:

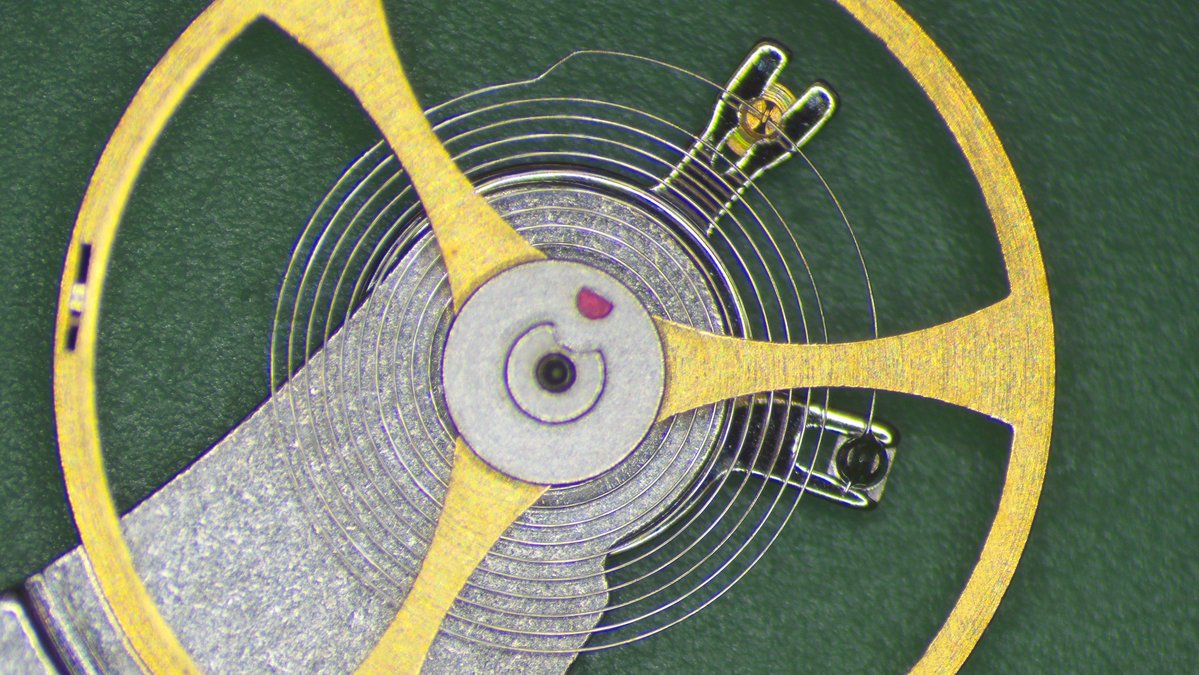

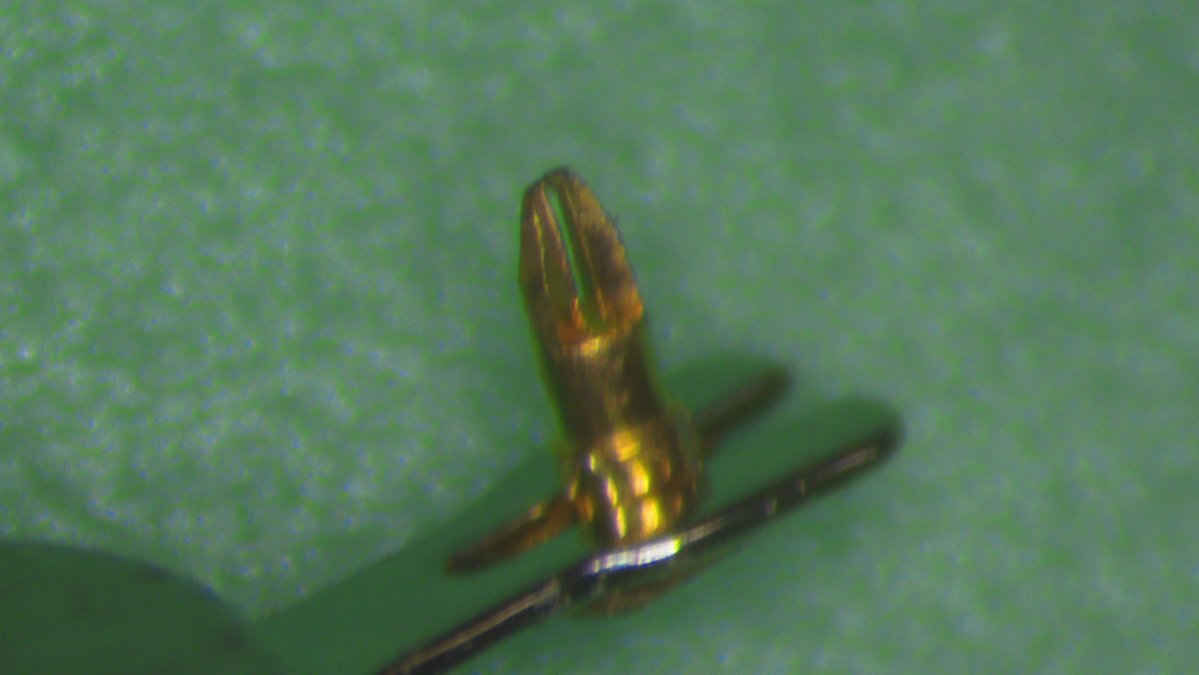

Regulator pin is closed on the end, so the hairspring will need to be slotted in from the side:

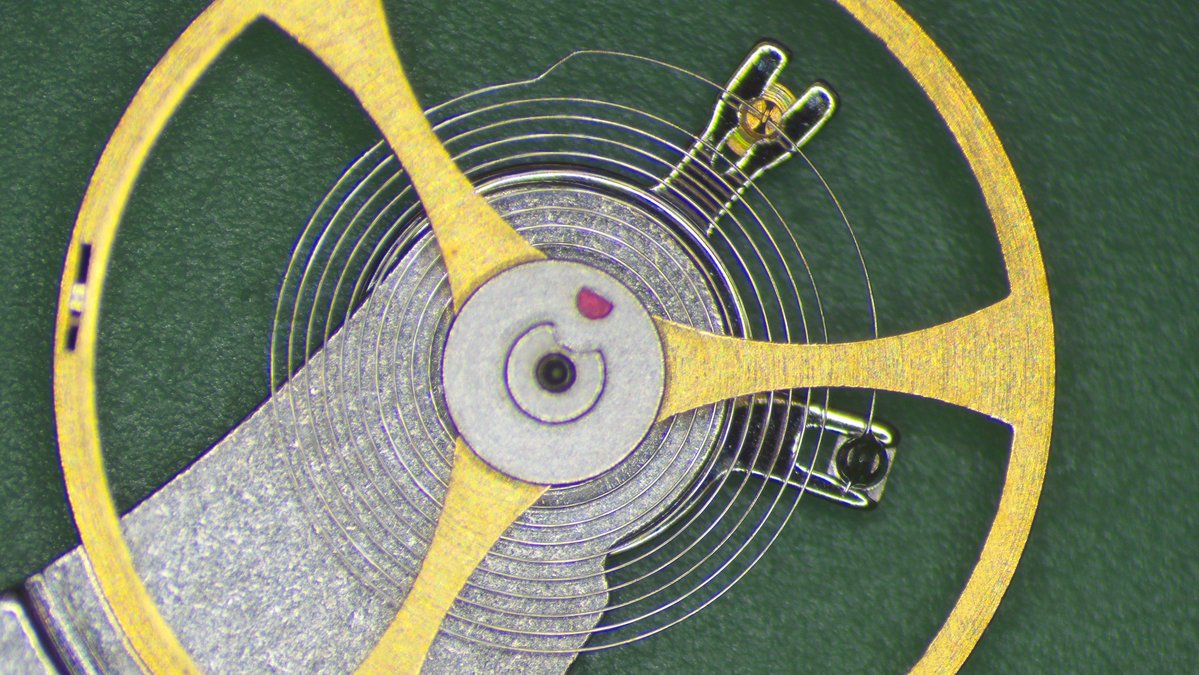

Hairspring is threaded through the regulator. I used a working balance to aim the roller jewel in the right direction, with the intention of fine tuning later:

I used UV glue, applied by a red oiler:

My improvised UV curing setup

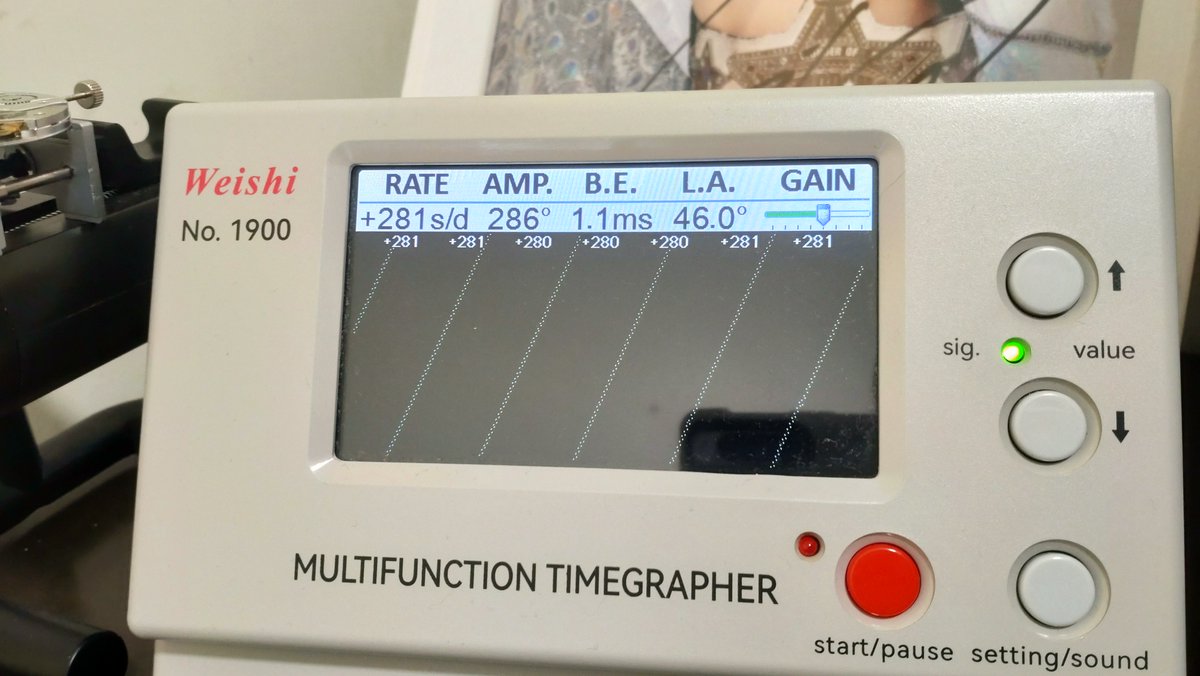

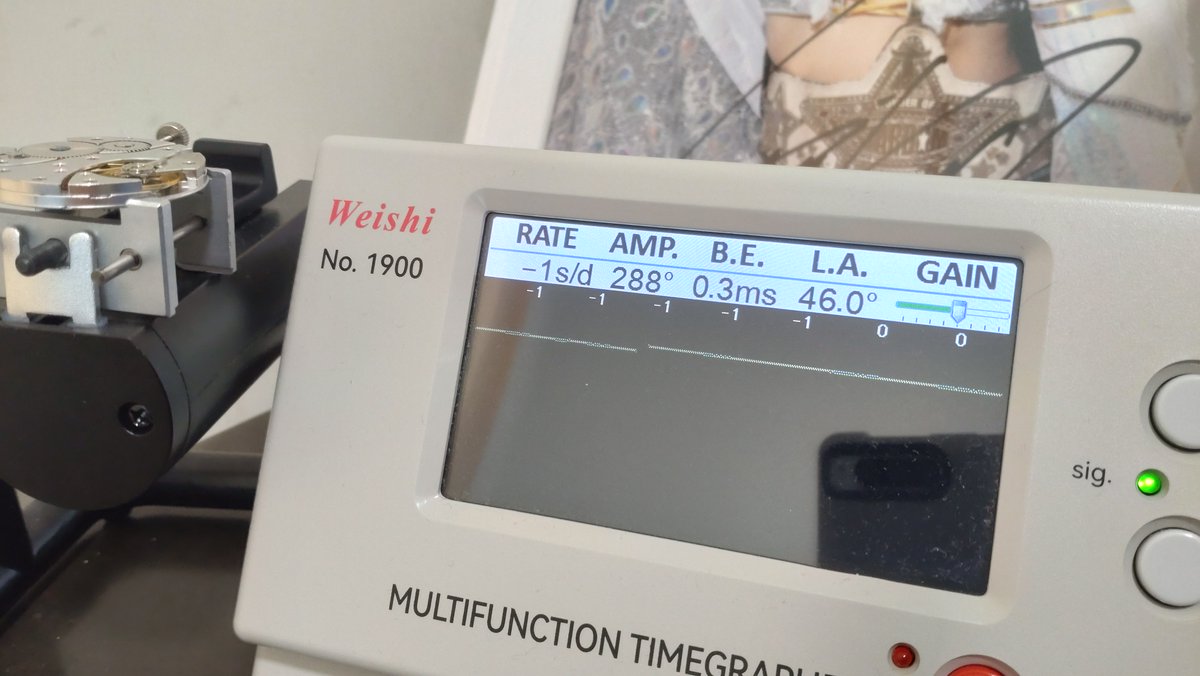

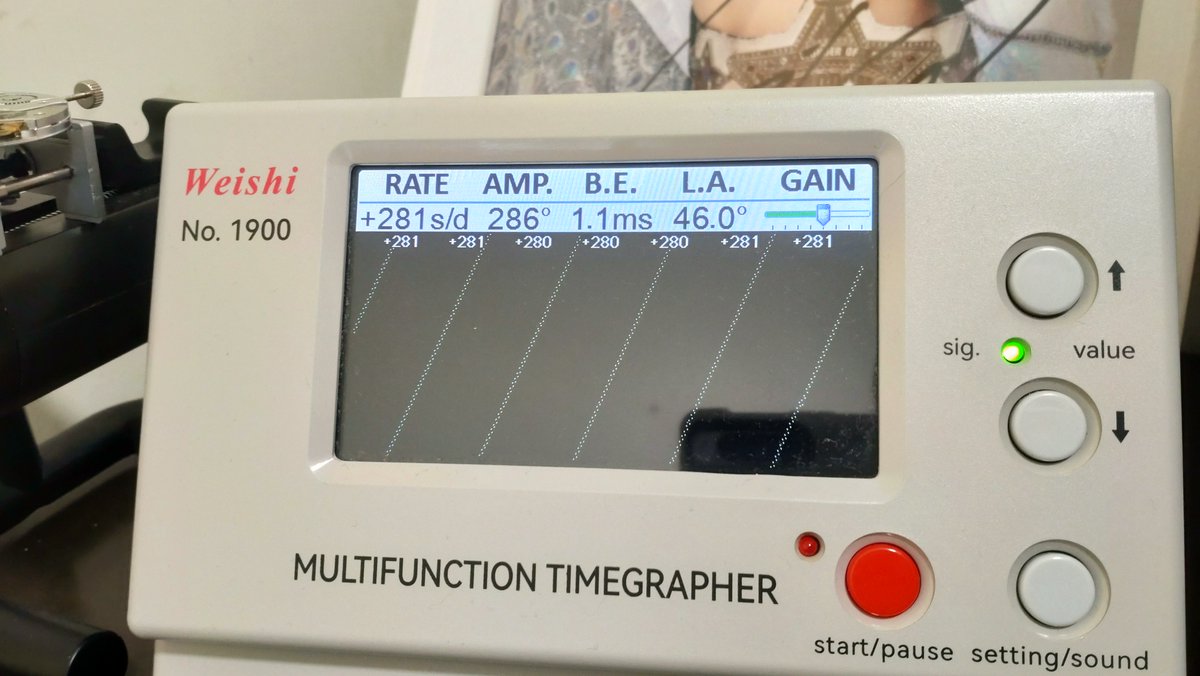

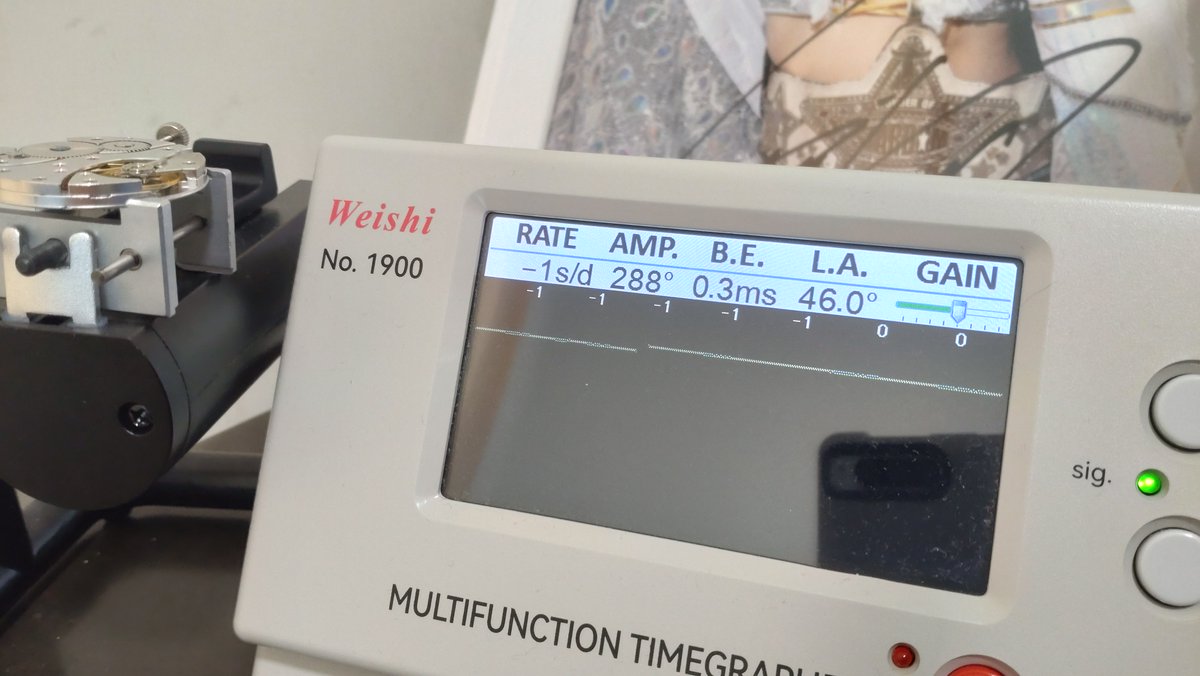

Initial timings look promising! I got it to 1.1 just by eyeballing it

My only goal was to get it within spec roughly in one position. I'll look at the rest later

I guess the main thing I learned during this time is that using a microscope has completely changed what I can do, in every task related to watch repair it can be applied to. I feel like I have really good control over the smallest parts, as long as I can see it clearly. I was struggling quite a bit using loupes.

You are currently viewing our boards as a guest which gives you limited access to view most discussions and access our other features. By joining our free community you will have access to post topics, communicate privately with other members (PM), respond to polls, upload content and access many other special features. Registration is fast, simple and absolutely free so please, join our community today!

The banners on the left side and below do not show for registered users!

You are currently viewing our boards as a guest which gives you limited access to view most discussions and access our other features. By joining our free community you will have access to post topics, communicate privately with other members (PM), respond to polls, upload content and access many other special features. Registration is fast, simple and absolutely free so please, join our community today!

The banners on the left side and below do not show for registered users!